Call Us

08045812837

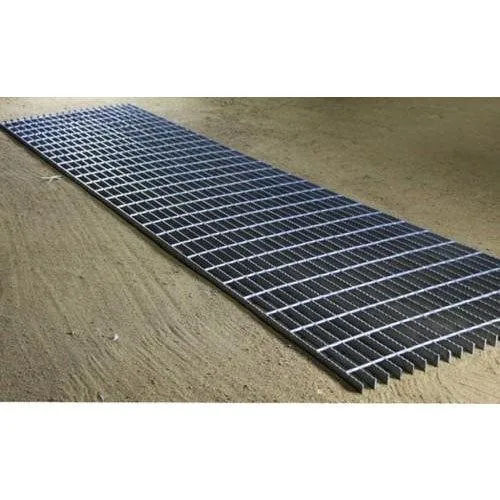

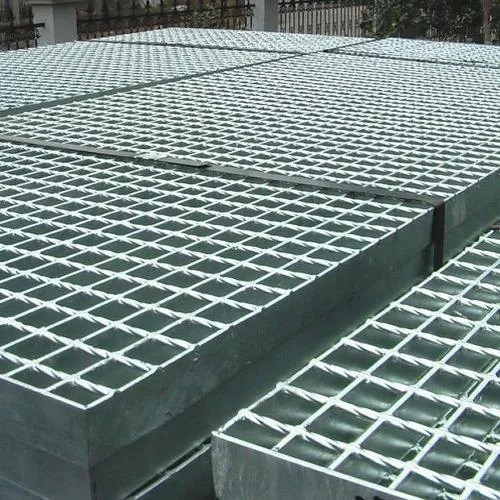

Galvanized Iron Gratings

100.00 INR/Kilograms

Product Details:

- Usage Construction

- Material Iron

- Size Standard

- Application Industrial

- Product Type Galvanized Iron Gratings

- Surface Treatment Galvanized

- Color Silver

- Click to view more

X

Galvanized Iron Gratings Price And Quantity

- 500 Kilograms

- 100.00 INR/Kilograms

Galvanized Iron Gratings Product Specifications

- Iron

- Silver

- Galvanized

- Standard

- Construction

- Industrial

- Galvanized Iron Gratings

Galvanized Iron Gratings Trade Information

- 10000 Kilograms Per Day

- 3-4 Week

Product Description

We bring forth a range of galvanised iron gratings that significantly combine the strength of iron or steel with the protective benefits of galvanization to provide a cost-effective and long-lasting solution for a variety of applications. The strength and load-bearing capability of iron gratings is one of its major features. The iron or steel material, along with the galvanised coating, creates a strong and durable structure capable of withstanding enormous loads without substantial deflection or damage. Galvanised iron gratings are profusely used in many industries, including manufacturing, building, natural gas and oil transportation, and water treatment plants.

High-Performance Industrial Solutions

Our Galvanized Iron Gratings are engineered to meet the rigorous demands of construction and industrial sectors. The galvanized finish enhances their longevity by providing superior resistance against rust and wear, ensuring that these gratings maintain their structural integrity over time. With standard sizes conveniently available, installation and maintenance become straightforward for any project scale.

Versatile Uses and Nationwide Supply

Ideal for walkways, platforms, drainage covers, and more, these gratings are suitable for various settings across India. We cater to diverse client requirements, ensuring timely delivery and consistent product quality. As both manufacturer and distributor, we are equipped to handle bulk orders as well as customized requests, maintaining competitive pricing and prompt service.

FAQ's of Galvanized Iron Gratings:

Q: How are Galvanized Iron Gratings manufactured?

A: Galvanized Iron Gratings are made from high-quality iron, which is shaped into standard-sized panels. These panels are then coated with a layer of zinc through the galvanization process, enhancing their resistance to corrosion and environmental wear.Q: What is the primary benefit of using galvanized gratings in construction and industrial settings?

A: The main advantage is their exceptional durability and ability to withstand harsh conditions. The galvanized surface protects the iron from rust and chemical exposure, making them ideal for both indoor and outdoor usage, particularly in demanding environments.Q: When should galvanized gratings be chosen over other types of floor coverings?

A: They are recommended when strong load-bearing capacity, slip resistance, and corrosion protection are essential, such as in factories, warehouses, construction sites, and processing plants.Q: Where can these galvanized iron gratings be installed?

A: These gratings are versatile and can be fitted in industrial floors, walkways, platforms, trench covers, and around drainage systems, providing safe and reliable surfaces in commercial and industrial locations.Q: What is the process of galvanizing iron gratings?

A: The iron gratings undergo a hot-dip galvanization process in which the fabricated panels are immersed in molten zinc. This process forms a durable, protective coating that significantly increases longevity and resistance to rust.Q: How can these gratings be beneficial for industrial facilities in India?

A: They help ensure workplace safety by delivering non-slip, sturdy surfaces, support effective drainage, and reduce long-term maintenance costs, making them a valuable addition to any industrial infrastructure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese