Call Us

08045812837

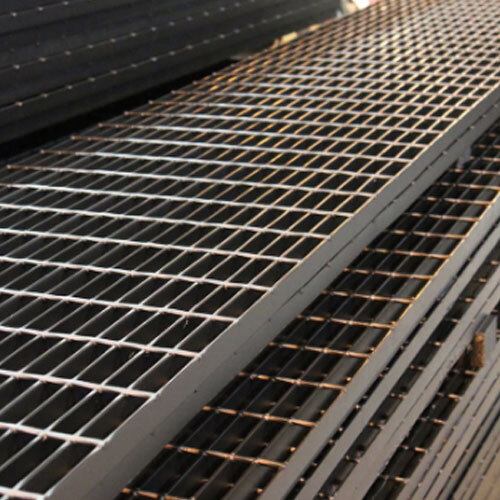

Electroforged Grating

98 INR/Kilograms

Product Details:

- Shape Rectangle

- Usage Trench Covers, Architectural, Walkways, Stairways, Reinforcement

- Material Other

- Application Grating

- Surface Treatment Electroforged

- Product Type Electroforged Grating

- Size 5 mm

- Click to view more

X

Electroforged Grating Price And Quantity

- 500 Kilograms

- 98 INR/Kilograms

Electroforged Grating Product Specifications

- Grating

- Grey

- Other

- Trench Covers, Architectural, Walkways, Stairways, Reinforcement

- Rectangle

- Electroforged

- 5 mm

- Electroforged Grating

Electroforged Grating Trade Information

- 10000 Kilograms Per Day

- 3-4 Week

Product Description

- Load Capacity : Heavy Duty

- Material : Mild Steel

- Thickness : 5 mm

- Flooring systems, Drainage, Grating Fence, Industrial,

- Usage/Applications : Trench Covers, Architectural, Walkways, Stairways, Reinforcement

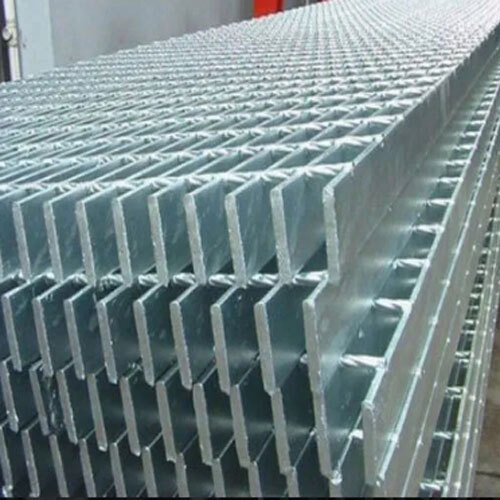

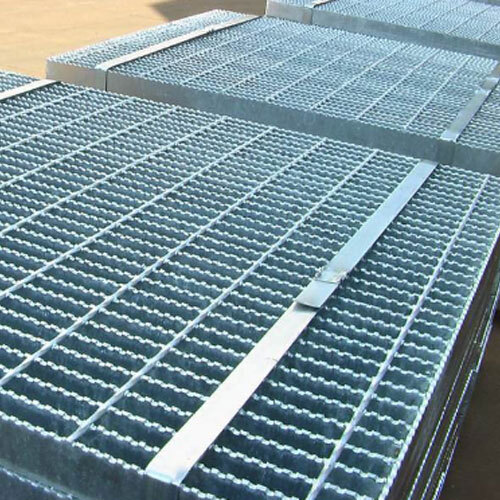

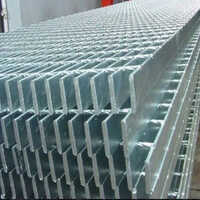

These gratings manufactured using electrical resistance welding technology. Ideal for industrial flooring, stair treads, platforms, drainage systems, and architectural applications.

Sturdy and Versatile Construction

Electroforged gratings offer exceptional load-bearing capacity, thanks to the advanced electroforged process that ensures uniform welds and rigidity. Their rectangular design, combined with a consistent 5mm thickness, makes them ideal for demanding settings such as trench covers and safety walkways.

Ideal for Multiple Applications

From reinforcing structural elements to providing safe access in walkways and stairways, these gratings are built for diverse uses. Their neutral grey finish suits architectural projects, while their robust material offers long-term performance in both indoor and outdoor environments.

FAQ's of Electroforged Grating:

Q: How is electroforged grating manufactured?

A: Electroforged grating is produced by fusing bearing bars and cross rods together using a combination of electrical current and pressure. This method creates a secure, uniform bond that results in enhanced strength and load distribution.Q: What are the main applications of electroforged grating?

A: Electroforged grating is commonly used for trench covers, architectural details, walkways, stairways, and reinforcement. Its sturdy design makes it suitable for both functional and aesthetic applications in public and industrial spaces.Q: When should I choose electroforged grating for my project?

A: Electroforged grating is ideal when your project requires reliable strength, slip resistance, and longevity. It's particularly suited for heavy-traffic areas, safety zones, and places where structural reinforcement is essential.Q: Where can electroforged gratings be installed?

A: These gratings are highly adaptable and can be installed in various environments such as industrial floors, commercial buildings, infrastructure projects, and anywhere safety and durability are priorities.Q: What are the advantages of the 5mm thickness and grey finish?

A: The 5mm thickness ensures excellent load-bearing capability, making the grating fit for high-stress uses. The grey color provides a neutral aesthetic compatible with architectural projects while resisting visible wear and tear.Q: How do I maintain electroforged grating for extended use?

A: Routine inspection and cleaning, combined with proper installation and surface treatment where needed, will help maintain functionality and prolong the life of the electroforged grating in your application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free